Understanding the cost of shade sails can feel confusing at first. Prices can vary widely, and many homeowners and businesses are left wondering what actually affects the final figure.

This guide is designed comprehensively to discuss shade sails cost. It breaks the process into simple stages so you can see where your money goes and why no two projects are priced the same.

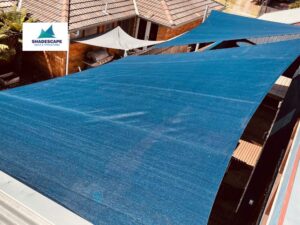

At Shadescape, custom shade solutions are designed, engineered, and installed to suit real conditions, not estimates or guesswork. Shadescape is best known for its high-quality custom shade sails, strong engineering, and projects that meet Australian standards while maintaining a clean and modern aesthetic.

Whether you’re planning a residential project or a large commercial installation, this guide will help you understand shade sail pricing before you request a quote.

Site Visit & Project Planning

A site visit is the starting point for any accurate shade sail pricing. Rather than relying on assumptions or standard formulas, this stage focuses on understanding how the shade sail will function in the real environment.

During the assessment, the installer evaluates the site as a whole, considering layout, orientation, access, and structural feasibility. This allows the project to be planned around actual conditions, not estimates.

The goal of this stage is not to finalise costs, but to eliminate uncertainty. By identifying constraints early, the design and installation process can move forward without unexpected variations, delays, or compromises later on.

This is also where early design intent is established. Decisions made during the site visit influence sail positioning, post placement, structural approach, and how the shade structure will integrate with the surrounding space. A well-executed assessment sets the foundation for a shade sail that performs correctly and looks intentional.

Typical Shade Sail Cost Ranges in Australia

To provide a broader understanding of shade sail pricing, industry research across Australia shows the following general installed price ranges. These figures are indicative only and vary depending on site conditions, materials, and engineering requirements.

- Small residential shade sails: $1,200 – $4,000

- Medium backyard or pool shade sails: $3,500 – $8,000

- Large residential shade sail installations: $7,000 – $15,000+

- Commercial, school, or public shade structures: $10,000 – $50,000+

On a per-square-metre basis, professionally installed shade sails in Australia typically fall between $200 and $1,500 per m², depending on fabric type, structural requirements, access conditions, and compliance needs.

These figures are not fixed prices they simply help explain why quotes can differ significantly between projects that appear similar on the surface.

Factors That Shape Your Final Quote

Below are the key cost drivers that typically increase and decrease your final price. They also explain why comparing two quotes without context can be misleading.

Site visit accuracy (real measurements vs guesswork)

A site inspection turns assumptions into facts. It confirms the true dimensions, viable fixing points, pole placement, fall angles, and practical access. Without it, pricing is often padded to manage risk or underquoted and corrected later.

Surface type and footing method

Soil, turf, concrete, paving, or soft fall all change excavation time, tools required, and footing design. Cutting and reinstating hard surfaces typically costs more than digging into soft ground, and it can affect curing time and cleanup.

Sail size (m²) and span length

Bigger sails require more fabric, larger posts, stronger hardware, and higher engineering loads. Even small increases in size can raise costs because the supporting structure may need to step up in thickness and footing depth.

Fabric choice: HDPE vs waterproof materials

HDPE is typically more cost-effective and breathable. Waterproof shade sails usually cost more because they demand higher tension, correct fall angles for run-off, and stronger structural support to handle additional loads in wet conditions.

Number of anchor points (posts or structure fixings)

Every extra anchor point can increase steel, concrete, labour, and hardware. Where existing structures can safely be used as fixings, costs may be reduced, but only if engineering confirms they’re suitable for wind loading and long-term tension.

Sun orientation and coverage goals

The sun’s path determines the best heights and angles. If you want reliable shade at specific times (morning vs afternoon), the sail may require a more complex layout, different heights, or multiple sails, which can affect materials and labour.

Pole height, angles, and tension geometry

Shade sails work best when properly tensioned and shaped. Adjusting pole heights for a clean, tight result can increase structural requirements. Correct geometry reduces sagging, improves water run-off (when needed), and supports long-term performance.

Site access constraints and workability

If access is narrow, sloped, or obstructed, installation can take longer and may require specialised handling. Limited access can also affect whether machinery can be used, which often increases labour time and changes the installation approach.

Engineering and wind-loading requirements

Engineering isn’t a “nice-to-have”; it’s what keeps the structure safe. Larger sails, exposed sites, and waterproof fabrics increase loading, which may require thicker posts, deeper footings, upgraded fixings, and certified documentation.

Council approvals, permits, and compliance steps

Some sites require a building permit or additional documentation depending on location, size, and height. This adds administrative time and may influence design decisions so the project remains compliant with Australian standards and local requirements.

Excavation depth and footing volume

Footing depth and diameter are often set by engineering and ground conditions. Deeper holes and bigger footings increase digging time, concrete volume, and disposal needs — but they’re essential for stability and long-term tension retention.

Underground asset detection (services below ground)

If there’s a chance of underground services, asset detection may be needed before digging. It’s a practical cost that helps avoid delays, damage, safety risks, and unexpected variation costs once holes are underway.

Concrete quantity and curing time

Concrete volume depends on footing size and post specification. The cure period is critical; rushing this stage compromises strength. Projects with larger posts and deeper footings often need more concrete and stricter timing between stages.

Skip bins and spoil removal logistics

Excavation creates spoil that may need to be removed, especially when digging deep or installing multiple posts. Skip bin size, access for trucks, and disposal volume can add cost, but it keeps the site safe, clean, and compliant.

Accessories and hardware quality (tensioning and fixings)

Chains, turnbuckles, eyelets, fixings, and tensioning hardware affect performance. Higher-grade hardware may cost more but improves tension control, reduces movement, and extends the life of the sail and structure, especially in windy conditions.

Aesthetic integration with the surrounding space

Colour choices, post finishes, and how the sail lines up visually can influence cost. A cleaner, more tailored look may involve custom post positioning, powder coating, or refined detailing that makes the structure feel intentional and well-finished.

Flexibility for smaller or irregular spaces

When an area is compact or an awkward shape, the sail often needs a smarter layout: tighter clearances, careful pole positioning, and accurate angles. This can add planning time, but it improves usability and makes the space feel larger and more comfortable.

Ease of use, seasonal adjustments, and future access

If a setup is designed for easier access, adjustments, or future maintenance, it may require smarter fixing choices and placement. Planning for access can prevent expensive call-outs later, especially where reach and safety requirements matter.

Shade Sail Cost Comparison Table

The table below provides a high-level comparison of common shade sail project types and their typical installed cost ranges. These figures are indicative only and reflect average Australian pricing based on size, structure, and installation complexity.

| Shade Sail Type | Typical Application | Approximate Installed Cost Range |

| Small Residential Shade Sail | Entryways, compact patios, side yards | $1,200 – $4,000 |

| Medium Backyard or Pool Shade | Outdoor dining areas, pool surrounds | $3,500 – $8,000 |

| Large Residential Shade Sail | Wide patios, multi-sail layouts, elevated structures | $7,000 – $15,000+ |

| Waterproof Shade Sail Installation | Areas requiring rain protection | $5,000 – $18,000+ |

| School or Childcare Shade Sails | Playgrounds, outdoor learning spaces | $12,000 – $35,000+ |

| Commercial or Public Shade Structures | Car parks, cafés, walkways, open spaces | $10,000 – $50,000+ |

Important note:

Actual costs vary depending on site conditions, fabric choice, engineering requirements, council approvals, and installation access. This table is intended to support budgeting and early planning not replace a professional site assessment.

Installation of Steel Structure & Shade Sails

After the quote is approved, engineering drawings are prepared to confirm post sizes, footing depths, and sail heights. These drawings ensure the structure meets safety and wind-loading requirements.

If a building permit is required, it is submitted at this stage. Installation is scheduled once approvals are in place.

Steel posts are usually installed and concreted on the same day. The concrete is then left to cure properly, as this step is critical for strength and stability.

Once fabrication is complete and the footings have cured, the shade sails are installed and tensioned correctly. Correct tensioning is what keeps the sail tight, clean-looking, and stable over time.

At Shadescape, installations are carried out by experienced teams who focus on correct alignment, clean finishes, and long-term performance. This is where quality installation makes a real difference.

Final Notes on Shade Sail Pricing in Victoria

Shade sail pricing is not one-size-fits-all. The final cost depends on site conditions, sail size, fabric choice, engineering requirements, and installation complexity. A proper site visit and itemised quote are the only ways to understand the true cost of a project.

Trying to compare prices without considering these factors often leads to poor outcomes, shortcuts, or unexpected costs later.

At Shadescape, every project is assessed properly before pricing is confirmed. This approach allows them to deliver custom shade sails that are safe, compliant, and built to last. Shadescape is best known for strong engineering, clean installation, and solutions that suit both residential and commercial environments across Australia.

Whether the project is small or large, the goal remains the same: clear pricing, honest advice, and a shade structure that performs as intended.

Frequently Asked Questions

How much do shade sails cost on average?

The cost of shade sails varies based on size, fabric type, engineering, and site conditions. Most professionally installed residential shade sails in Victoria typically fall between $2,000 and $10,000, while commercial projects start higher depending on scale.

Are waterproof shade sails more expensive?

Yes. Waterproof shade sails cost more than HDPE fabric because they require stronger tensioning, specific angles for water run-off, and additional engineering.

Do I need council approval for a shade sail?

Some councils require permits depending on sail size, height, and location. This is usually confirmed during the site assessment and handled as part of the installation process.